Strain Rate & Fracture

Understanding how loading speed influences fracture behavior in layered 3D printed composites

Modern material performance is often judged using published values such as elastic modulus, flexural modulus, and flexural strength.

However, these values are derived under specific laboratory conditions — most commonly under quasi-static loading, where deformation occurs very slowly.

To understand real structural performance, it is essential to understand how strain rate influences fracture behavior.

This page explains that connection step by step.

What Is Quasi-Static Testing?

Standard Mechanical Testing Is Performed at Low Strain Rates

Most material properties in dentistry and polymer science are measured using a universal testing machine (such as an Instron system).

In a typical three-point bending test:

• A sample is supported at two points

• A load is applied slowly at the center

• The crosshead speed is very low

• Deformation occurs gradually

This is called quasi-static loading.

What Does Quasi-Static Mean?

Quasi-static means:

• Very low strain rate

• Gradual deformation

• Controlled stress increase

• Slow redistribution of internal stresses

Under these conditions:

• Polymer chains have time to rearrange

• Micromechanical interlayer bonds transfer stress effectively

•Pore laden Weak interfaces are not critically stressed

• Fracture mechanics may remain dormant in pore laden resin

This testing primarily measures intrinsic material properties.

What is material strain rate?

Strain Rate Determines How Fast Material Deformation Occurs

Strain rate describes how quickly a material is deformed.

Low strain rate: • Slow laboratory bending

• Controlled testing

• Gradual load application

High strain rate: • Sudden bite force as while biting over food

• Rapid occlusal contact

• Accidental drops

• Impact

• Fast cyclic loading which chewing on tough foods

The same material behaves differently depending on how much of porosity it contains and how fast it is loaded.

Why Speed Of Loading Changes Material Fracture Behavior

At low strain rates:

• Stress within material redistributes gradually

• Local stress concentrations in material have ample time to be relieved

• Material interfaces are less challenged

At high strain rates:

• Stress waves propagate rapidly

• Stress and Strain redistribution time is limited even though strain hardening may take place

• Interlayer shear becomes critical

• Crack initiation can occur quickly

This is where fracture mechanics becomes dominant.

Intrinsic Properties vs Structural Performance

Intrinsic Modulus Does Guarantee Structural Integrity Under Low Strain Rates But Not Under High Strain Rates

Intrinsic or Intensive material properties include:

• Elastic modulus (E)

• Flexural modulus

• Tensile strength

These are intensive properties. They describe the material itself. They do not depend on geometry.

However, structural performance during high strain rates depends on:

• Shear transfer between layers due to Mechanical Keying

• Resistance to material slip

• Moment of inertia (I)

• Bending stiffness (EI)

A composite material may have high intrinsic strength, and yet fail under dynamic loading if mechanical keying interaction between 3d -printed layers is insufficient and/or if the composite is full of nano-porosity.

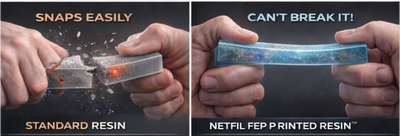

Why Layered Resin Prints Can Fracture Suddenly

In resin 3D- printing:

• Components are built layer by layer

• Layers bond primarily through chemical adhesion or bonding and nano-porosity is always present in the picture

• Interfacial bonding occurs at microscopic length scales and not at macroscopic length scales

Under fast or rampant loading conditions like simple manual hand bending of a bar of resin:

• Micromechanical bonds cannot transfer stresses and strains efficiently or quickly

• Fracture may initiate almost immediately

• Shear stresses increase rapidily

• Interfaces act as weak planes when nanopores are also present.

Failure during rampant or fast loading may still occur even if modulus and flexural strength values are high.

The limitation is in the structural stress-strain coupling or transfer, and also in the pore- free condition of the isotropic 3D -printed composite resin bar. Our Netfil process can be used to effectively remove pores from the resin.

Fracture Mechanics and Stress Redistribution

When Stress Redistribution Fails, Fracture Dominates

Under slow loading:

• Stress concentrations dissipate gradually

• Crack initiation is delayed

Under rapid loading:

• Stress concentrates quickly

• Shear stresses accumulate at interfaces

• Fracture mechanics governs failure

High modulus alone cannot prevent fracture if shear transfer between layers is insufficient under dynamic conditions.

Mechanical Keying and High Strain Rate Tolerance

This creates:

• Mechanical interlocking between layers

• Increased resistance to slip during high strain rates

• Improved interlayer shear transfer during high strain rates

Importantly, this does NOT change:

• Resin chemistry

• Intrinsic elastic modulus

• Biocompatibility

The improvement lies in macro mechanical keying under dynamic loading

Improvement In Stiffness

During bending evaluation, an increase in stiffness may be observed in the composite printed using our macrotexture FEP sheet.

In technical terms, this is often reflected as an increase in the secant modulus measured from the bending load–deflection curve. This increase in secant modulus is not an indication that the intrinsic elastic modulus of the resin has changed. Rather, it reflects an increase in the effective structural stiffness of the composite.

In other words, the secant modulus increase is indicative of improved resistance to bending deformation. But the more important feature is the improvement in the high strain-rate damage tolerance the FEP film brings to the 3d-printed composite

Netfil Clear edge Materials and Solutions

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.